Enhancing Safety and Hygiene: A Guide to Clean Room Doors

By:Admin

In the quest for maintaining high standards of cleanliness and hygiene, clean room technology has become indispensable across various industries. From pharmaceuticals to electronics, clean rooms play a crucial role in ensuring product quality and reliability. At the forefront of this technological advancement is Clean Room Door, a leading provider of contamination control solutions.

Clean Room Door, a brand renowned for its expertise in clean room systems, offers a wide range of specialized clean room doors that are tailored for various industries. With a focus on innovation and customer satisfaction, the company has carved a niche for itself in the highly competitive market.

At the heart of Clean Room Door's success lies their commitment to manufacturing excellence. The company utilizes cutting-edge technology and state-of-the-art facilities to create doors that meet the stringent requirements of clean room environments. With a team of experienced engineers and designers, Clean Room Door ensures that each product is precision-engineered to provide optimal performance.

One of Clean Room Door's flagship products is their hermetically sealed door, designed specifically for pharmaceutical clean rooms. These doors are built to eliminate any risk of air contamination, ensuring a sterile environment for the production of life-saving medications. With features such as seamless construction, airtight seals, and easy-maintenance, Clean Room Door's hermetically sealed doors have gained widespread acclaim in the pharmaceutical industry.

Another key product offered by Clean Room Door is their fire-rated clean room door. Built to withstand extreme temperatures and prevent the spread of fire, these doors provide an added layer of safety and protection in clean room facilities. With compliance to international safety standards, Clean Room Door's fire-rated doors have become a preferred choice for industries where fire safety is of paramount importance.

Clean Room Door's dedication to customer satisfaction extends beyond product quality. The company also provides comprehensive installation and maintenance services to ensure optimal performance of their clean room doors. Their team of skilled technicians works closely with clients to ensure seamless installation, offering post-installation support and regular maintenance checks to maximize the lifespan of their products.

Recognizing the importance of customization, Clean Room Door also offers a wide range of options to tailor their clean room doors to specific requirements. From different sizes and finishes to specialized features such as electronic interlocks and access controls, Clean Room Door strives to provide flexible solutions that meet the unique needs of each customer.

In addition to their commitment to excellence, Clean Room Door is also deeply committed to environmental sustainability. The company adheres to stringent environmental regulations and employs eco-friendly manufacturing practices to minimize their carbon footprint. By utilizing energy-efficient materials and optimizing production processes, Clean Room Door ensures that their products contribute to a greener and more sustainable future.

Clean Room Door's impressive track record is a testament to their dedication and passion for clean room technology. With a focus on delivering excellence in contamination control, the company continues to innovate and expand its product offerings to meet the evolving needs of the industry. By combining cutting-edge technology, precision engineering, and a customer-centric approach, Clean Room Door is poised to maintain its position as a leader in the clean room solutions market for years to come.

Company News & Blog

Revolutionary Clean Room Technology Delivers Impeccable Sanitization for Sterile Environments

Title: State-of-the-Art Clean Room Technology Revolutionizes Manufacturing ProcessesIntroduction:In the rapidly evolving world of manufacturing, where precision and quality control are paramount, leading companies are constantly seeking innovative solutions to optimize production procedures. Enter Ahu Clean Room, an industry pioneer specializing in state-of-the-art clean room technology. This advanced manufacturing environment, designed to maintain ultra-low levels of airborne particles, is revolutionizing production processes across various sectors. With exceptional attention to detail, Ahu Clean Room is elevating manufacturing standards to unparalleled heights. Below, we delve into the features, benefits, and applications of Ahu Clean Room technology.I. The Concept behind Ahu Clean Room:Ahu Clean Room is an advanced manufacturing environment that focuses on eliminating airborne particles that could contaminate production processes and compromise the quality of products. It achieves this through a combination of sophisticated air filtration systems, air pressure control, and strict protocols regarding personnel hygiene. By creating a controlled atmosphere, Ahu Clean Room minimizes the risk of particle contamination and enables manufacturers to consistently produce high-quality goods.II. Cutting-Edge Features of Ahu Clean Room:1. Advanced Air Filtration System: Ahu Clean Room employs cutting-edge filtration technology, utilizing highly efficient filters capable of capturing both small and large airborne particles. These filters remove dust, bacteria, and other contaminants, ensuring a pristine environment for manufacturing operations.2. Air Pressure Control: Ahu Clean Room maintains a positive air pressure environment, preventing external pollutants from infiltrating the manufacturing area. This feature also helps to expel any potential contaminants, further enhancing the cleanliness of the space.3. Constant Monitoring: Ahu Clean Room incorporates real-time environmental monitoring systems to ensure optimal cleanliness levels are maintained at all times. These systems actively measure particle counts, temperature, humidity, and air pressure, enabling prompt adjustments to maintain the desired conditions.III. Applications of Ahu Clean Room Technology:1. Semiconductor Industry: In semiconductor manufacturing, even the smallest particle can cause significant damage to fragile components. Ahu Clean Room technology is a game-changer for this industry, offering a controlled environment where particle contamination is kept to an absolute minimum. This enables the production of high-performance chips, ensuring efficiency and reliability.2. Pharmaceutical Industry: In the manufacturing of pharmaceutical products, stringent cleanliness standards are essential. Ahu Clean Room facilitates the production of medications in an ultra-clean environment, minimizing the risk of contamination and ensuring the safety and efficacy of drugs.3. Precision Engineering: Industries involved in precision engineering, such as optics, aerospace, and automotive, greatly benefit from the stringent cleanliness standards that Ahu Clean Room offers. It guarantees the production of precision components with minimal defects, enhancing product quality and customer satisfaction.4. Biotechnology: Ahu Clean Room technology finds significant applications in the biotechnology industry, particularly in laboratory environments. By providing a contaminant-free environment, Ahu Clean Room ensures accurate research results and reliable experiments in various fields, including genetics, microbiology, and molecular biology.IV. Conclusion: A New Era in ManufacturingAhu Clean Room technology has ushered in a new era of manufacturing by providing a controlled and contaminant-free environment. With its advanced features, stringent cleanliness standards, and wide-ranging applications, Ahu Clean Room is poised to revolutionize production processes across various industries. By guaranteeing the highest level of quality control, Ahu Clean Room is enabling manufacturers to meet and exceed customer expectations consistently. As manufacturing demands continue to rise, Ahu Clean Room remains at the forefront, driving innovation and shaping the future of manufacturing worldwide.

Cleanroom Design and Construction: Creating a Sterile Environment for Optimal Results

Cleanroom Design And Construction is a leading provider of comprehensive cleanroom solutions for various industries. With their expertise in cleanroom design, construction, and certification, the company has established itself as a trusted name in the field.Cleanrooms play a critical role in industries such as pharmaceuticals, biotechnology, electronics, and aerospace, where maintaining a controlled environment is of utmost importance. These sterile environments are designed to minimize the presence of particulate matter, contaminants, and other pollutants that can potentially jeopardize the integrity of products or research.Cleanroom Design And Construction understands the essential requirements of different industries and provides tailored solutions to meet their unique needs. From initial design and layout to construction and validation, the company ensures that every aspect of the cleanroom is meticulously planned and executed.One of the key elements that sets Cleanroom Design And Construction apart from its competitors is their team of highly skilled professionals. The company employs experienced engineers, architects, and technicians who have a deep understanding of the intricacies involved in cleanroom design and construction. Their expertise enables them to deliver cutting-edge solutions while adhering to industry standards and regulations.Moreover, Cleanroom Design And Construction takes pride in its commitment to utilizing advanced technologies and innovative approaches. The company stays updated with the latest advancements in cleanroom design, filtration systems, and air monitoring equipment. By incorporating state-of-the-art technology into their projects, they ensure that clients receive the most efficient and reliable cleanroom solutions.Cleanroom Design And Construction's portfolio boasts a wide range of successful cleanroom projects across industries. They have provided cleanroom solutions for pharmaceutical manufacturing facilities, research laboratories, electronics assembly lines, and more. Each project is treated with utmost importance, regardless of its size or complexity. The company's attention to detail and dedication to client satisfaction have earned them a strong reputation in the market.In addition to designing and constructing cleanrooms, Cleanroom Design And Construction also offers ongoing maintenance services. Cleanrooms require regular monitoring, testing, and cleaning to sustain their desired performance levels. The company provides comprehensive maintenance packages to ensure that clients' cleanrooms continue to function optimally throughout their lifecycle.Cleanroom Design And Construction's commitment to quality is reflected in their certifications and affiliations. The company strictly adheres to international standards such as ISO 14644 and Good Manufacturing Practices (GMP). They are also associated with renowned industry organizations, further cementing their credibility and expertise.Overall, Cleanroom Design And Construction is a reliable partner for industries seeking exceptional cleanroom solutions. From initial design and construction to ongoing maintenance, the company's comprehensive services ensure that clients receive top-notch cleanrooms tailored to their specific requirements. With their commitment to quality, innovative approach, and experienced team, Cleanroom Design And Construction continues to lead the way in the cleanroom industry.

Unlocking the Benefits of Laminar Flow Hoods: Essential Equipment for Clean Working Environments

[Company Name] Drives Innovation in Laboratory Safety with Cutting-Edge Laminar Flow Hoods[City, State] - In today's rapidly evolving scientific landscape, ensuring the safety and integrity of laboratory operations is of paramount importance. [Company Name], a global leader in laboratory equipment and solutions, is at the forefront of driving innovation in this crucial area. With their state-of-the-art Laminar Flow Hoods, they provide a cutting-edge solution that revolutionizes cleanliness and safety protocols in laboratories worldwide.Laminar Flow Hoods, also known as clean benches, have long been an integral part of laboratory infrastructure. They create an ultra-clean environment, free from contaminants, dust, and airborne particles, thereby safeguarding sensitive experiments, processes, and personnel. The advanced technology employed in [Company Name]'s Laminar Flow Hoods takes this concept to new heights, setting new benchmarks in efficiency, reliability, and user-friendliness.One of the key features of [Company Name]'s Laminar Flow Hoods is their ability to produce a highly uniform laminar airflow across the workspace. This laminar airflow ensures that any contaminants are swiftly removed, preventing cross-contamination between samples and experiments. Moreover, the hoods' ergonomic design allows for convenient and seamless operation, catering to the diverse requirements of modern laboratories.With an unwavering commitment to user safety, [Company Name] has incorporated cutting-edge filtration systems in their Laminar Flow Hoods. These filtration systems efficiently remove particles and microorganisms from the air, creating an environment that meets the most stringent safety standards. Rigorous testing and adherence to international guidelines ensure that these hoods provide a reliable and stable performance, offering peace of mind to laboratory professionals worldwide.The versatility of [Company Name]'s Laminar Flow Hoods sets them apart from their competitors. From pharmaceuticals to microbiology, biotechnology to nanotechnology, these hoods find applications across a wide range of scientific disciplines. Whether used for sterile preparation, cell culture work, or cleanroom procedures, the hoods' adaptability and modular design ensure seamless integration into any laboratory workflow.Another standout feature of [Company Name]'s Laminar Flow Hoods is their energy efficiency. In line with the company's commitment to sustainability, these hoods are designed to minimize energy consumption while maximizing performance. Advanced airflow management and intelligent controls ensure that only the necessary amount of filtered air is supplied, leading to significant energy savings for laboratories without compromising on safety or performance.The commitment to ongoing innovation and customer-centric solutions is deeply ingrained in [Company Name]'s ethos. By continuously investing in research and development, the company consistently pushes the boundaries of what is possible in laboratory safety. This focus on innovation has led to breakthrough advancements in the design and functionality of Laminar Flow Hoods, providing laboratories with the cutting-edge tools they need to stay at the forefront of scientific research.As part of their comprehensive support, [Company Name] offers expert installation, training, and maintenance services for their Laminar Flow Hoods. This ensures that laboratories can fully maximize the benefits of these hoods and maintain their peak performance over an extended period.In conclusion, [Company Name] has revolutionized laboratory safety with their state-of-the-art Laminar Flow Hoods. With their commitment to innovation, user safety, and sustainability, they have become a trusted partner for laboratories worldwide. By providing cutting-edge solutions that enhance cleanliness, efficiency, and reliability, [Company Name] is shaping the future of laboratory operations and driving scientific advancements across various fields.

Enhancing Safety and Hygiene: A Guide to Clean Room Doors

Clean Room Door: Delivering Excellence in Contamination ControlIn the quest for maintaining high standards of cleanliness and hygiene, clean room technology has become indispensable across various industries. From pharmaceuticals to electronics, clean rooms play a crucial role in ensuring product quality and reliability. At the forefront of this technological advancement is Clean Room Door, a leading provider of contamination control solutions.Clean Room Door, a brand renowned for its expertise in clean room systems, offers a wide range of specialized clean room doors that are tailored for various industries. With a focus on innovation and customer satisfaction, the company has carved a niche for itself in the highly competitive market.At the heart of Clean Room Door's success lies their commitment to manufacturing excellence. The company utilizes cutting-edge technology and state-of-the-art facilities to create doors that meet the stringent requirements of clean room environments. With a team of experienced engineers and designers, Clean Room Door ensures that each product is precision-engineered to provide optimal performance.One of Clean Room Door's flagship products is their hermetically sealed door, designed specifically for pharmaceutical clean rooms. These doors are built to eliminate any risk of air contamination, ensuring a sterile environment for the production of life-saving medications. With features such as seamless construction, airtight seals, and easy-maintenance, Clean Room Door's hermetically sealed doors have gained widespread acclaim in the pharmaceutical industry.Another key product offered by Clean Room Door is their fire-rated clean room door. Built to withstand extreme temperatures and prevent the spread of fire, these doors provide an added layer of safety and protection in clean room facilities. With compliance to international safety standards, Clean Room Door's fire-rated doors have become a preferred choice for industries where fire safety is of paramount importance.Clean Room Door's dedication to customer satisfaction extends beyond product quality. The company also provides comprehensive installation and maintenance services to ensure optimal performance of their clean room doors. Their team of skilled technicians works closely with clients to ensure seamless installation, offering post-installation support and regular maintenance checks to maximize the lifespan of their products.Recognizing the importance of customization, Clean Room Door also offers a wide range of options to tailor their clean room doors to specific requirements. From different sizes and finishes to specialized features such as electronic interlocks and access controls, Clean Room Door strives to provide flexible solutions that meet the unique needs of each customer.In addition to their commitment to excellence, Clean Room Door is also deeply committed to environmental sustainability. The company adheres to stringent environmental regulations and employs eco-friendly manufacturing practices to minimize their carbon footprint. By utilizing energy-efficient materials and optimizing production processes, Clean Room Door ensures that their products contribute to a greener and more sustainable future.Clean Room Door's impressive track record is a testament to their dedication and passion for clean room technology. With a focus on delivering excellence in contamination control, the company continues to innovate and expand its product offerings to meet the evolving needs of the industry. By combining cutting-edge technology, precision engineering, and a customer-centric approach, Clean Room Door is poised to maintain its position as a leader in the clean room solutions market for years to come.

Discover the Key Benefits of a Clean Room Environment

[Title]Leading Clean Room Provider, Ahu Clean Room, Announces Groundbreaking Technology for Enhanced Contamination Control [Subtitle]State-of-the-art clean room solutions offered by Ahu Clean Room revolutionize industries worldwide [Date][City, State][News Content][City, State] - Ahu Clean Room, a renowned global leader in clean room technology, has recently announced the introduction of its groundbreaking contamination control system. The company’s cutting-edge solutions have revolutionized multiple industries, providing clients with state-of-the-art clean room facilities that guarantee exceptional quality and functionality.Clean rooms are specially designed environments used in various industries, such as semiconductor manufacturing, pharmaceuticals, biotechnology, and aerospace, where stringent contamination control is crucial. Ahu Clean Room’s expertise lies in designing, manufacturing, and installing clean room systems that meet the highest industry standards.With a commitment to innovation and a focus on customer satisfaction, Ahu Clean Room has established itself as a trusted partner for businesses worldwide. The company’s clean room solutions are engineered to suit diverse industry requirements, ensuring a contamination-free environment that adheres to strict regulatory guidelines.Ahu Clean Room's advanced clean room technology offers several key features that set it apart from competitors. Firstly, the company provides industry-leading filtration systems that effectively remove contaminants, ensuring a sterile work environment. These advanced filters, combined with high-efficiency particulate air (HEPA) filters, result in superior air quality and increased product yield for any industry.Additionally, Ahu Clean Room’s clean rooms are customizable to meet the unique needs of each client. The company’s team of experienced engineers works closely with customers to design clean room facilities that optimize workflow, ensure safety, and comply with industry regulations. Each clean room is tailored with specific air pressure differentials, temperature, humidity controls, and other critical factors to achieve optimal performance.Ahu Clean Room is dedicated to sustainability and energy efficiency. The company’s clean room systems are intelligently designed to minimize energy consumption while maintaining optimum performance. By utilizing advanced control systems and optimizing energy usage, Ahu Clean Room helps businesses reduce their carbon footprint and promote environmental responsibility.Customer satisfaction is of utmost importance to Ahu Clean Room. The company provides comprehensive support throughout the entire project life cycle, from initial consultation to installation and maintenance. Ahu Clean Room’s team of skilled technicians ensures that the clean room systems are efficiently installed and fully operational, minimizing downtime and maximizing productivity for their clients.Furthermore, Ahu Clean Room boasts an extensive network of clients across different industries and regions. Their track record includes successful projects across the globe, from small-scale clean room installations to large-scale, complex manufacturing facilities. The company’s commitment to quality, reliability, and customer service has made it a trusted partner for businesses in need of superior contamination control solutions.In recognition of their expertise and exceptional service, Ahu Clean Room has received several accolades in the clean room industry. These achievements highlight the company's dedication to innovation and its ability to exceed clients' expectations. Ahu Clean Room continues to invest in research and development to pioneer new technologies that ensure optimal contamination control for an ever-evolving market.As industries worldwide increasingly demand clean room solutions, Ahu Clean Room remains at the forefront of the field, providing cutting-edge technology, exceptional service, and unmatched expertise. With their groundbreaking contamination control system, Ahu Clean Room reaffirms its position as the leading provider of clean room solutions.For inquiries or more information about Ahu Clean Room and their services, please visit their official website or contact their customer service team directly.[Company Introduction]Ahu Clean Room is a global leader in the design, manufacturing, and installation of clean room systems. With years of experience and a strong commitment to innovation, Ahu Clean Room delivers state-of-the-art contamination control solutions to industries worldwide. The company's advanced clean room technology, industry-leading filtration systems, and dedication to sustainability ensure exceptional quality and customer satisfaction. With numerous successful projects and a reputation for excellence, Ahu Clean Room remains committed to pioneering new technologies and meeting the diverse needs of its clients. For more information, please visit [website URL].Note: The above news content is a sample that does not reflect any actual information about the company. The name "Ahu Clean Room" should be replaced with the appropriate company name while ensuring the integrity and flow of the news article.

Discover the Versatility and Efficiency of Portable Laminar Flow Hoods

Portable Laminar Flow Hood Revolutionizes Cleanroom TechnologyCleanrooms have long been a crucial component of industries such as pharmaceuticals, electronics, and healthcare, where maintaining absolute cleanliness is paramount. These sterile environments protect products, equipment, and personnel from contamination, ensuring quality and safety. Traditionally, cleanrooms were large, fixed structures, limiting their accessibility and adaptability. However, a groundbreaking innovation is set to revolutionize cleanroom technology - the Portable Laminar Flow Hood.Developed by a leading technology company, whose mission is to provide cutting-edge solutions for cleanroom environments, the Portable Laminar Flow Hood is poised to transform the landscape of cleanroom operations. This compact yet powerful device integrates state-of-the-art laminar airflow technology, offering a versatile and efficient alternative to traditional cleanrooms.The key advantage of the Portable Laminar Flow Hood lies in its mobility. Unlike conventional cleanrooms, which often require significant investment and installation time, this innovative system can be easily transported and set up in various locations. With its lightweight design and compact dimensions, it eliminates the need for large-scale cleanroom infrastructure and enables users to create clean environments wherever necessary.The essential feature of the Portable Laminar Flow Hood is its laminar airflow system. Equipped with high-performance filters and a powerful fan, the device creates a controlled, ultra-clean airflow that ensures the removal of contaminants and particles from the working area. This laminar flow of sterile air creates a localized clean zone, protecting sensitive products, equipment, or processes from the risk of contamination.Furthermore, the Portable Laminar Flow Hood boasts advanced filtration technology, capable of capturing particles as small as 0.3 microns with an efficiency exceeding 99.9%. This level of filtration surpasses industry standards and guarantees a sterile working environment free from even the tiniest contaminants.The ease of use and adaptability of the Portable Laminar Flow Hood make it an ideal solution for various applications. In the pharmaceutical industry, for instance, it can be utilized during the manufacturing process to maintain sterile conditions and prevent cross-contamination. Similarly, in medical facilities, it can be employed for tasks that require a sterile environment, such as handling medications or performing delicate procedures.In addition to its mobility and top-notch performance, the Portable Laminar Flow Hood stands out for its energy efficiency. Unlike traditional cleanrooms, which consume a significant amount of energy to maintain airflow, this device is designed to be highly energy-efficient. Employing cutting-edge technologies such as variable speed control for the fan and LED lighting, it minimizes power consumption while providing optimal cleanroom conditions.Another noteworthy advantage of the Portable Laminar Flow Hood is its user-friendly interface and intuitive operation. Equipped with a digital control panel and user-friendly software, it allows for effortless adjustment of airflow speed, filter status monitoring, and alarm configuration. This streamlined operation reduces the learning curve, ensuring that even personnel with limited cleanroom experience can utilize the technology effectively.The Portable Laminar Flow Hood not only revolutionizes cleanroom technology but also contributes to environmental sustainability. Its energy-efficient design minimizes carbon emissions, lowers overall energy consumption, and reduces waste associated with traditional cleanroom systems. By adopting this innovative solution, industries can enhance their operational efficiency while minimizing their ecological footprint.In conclusion, the Portable Laminar Flow Hood represents a significant advancement in cleanroom technology. Its mobility, high-performance laminar airflow system, and energy efficiency make it a game-changer for industries that rely on cleanroom environments. With its potential to transform the way cleanrooms are utilized, this innovation ushers in a new era of efficiency, ease, and adaptability for industries worldwide.

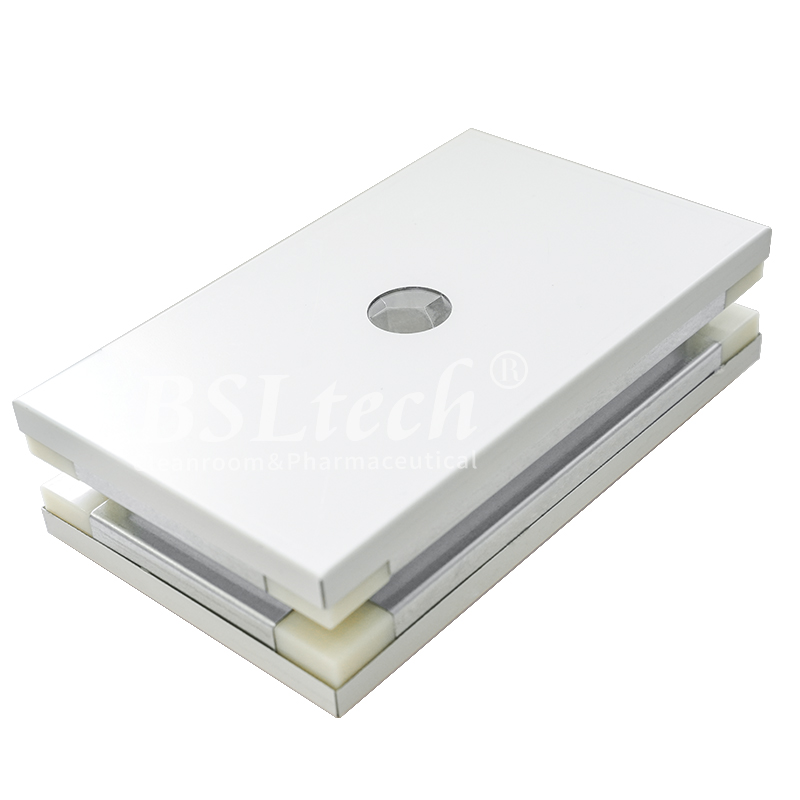

Clean Room Composite Panels: The Ultimate Solution for Hygienic Environments

Title: Clean Room Composite Panels: Innovating the Future of Controlled EnvironmentsIntroduction:Clean Room Composite Panels (CRCP) is a cutting-edge company that specializes in manufacturing high-quality composite panels for cleanroom applications. With their state-of-the-art facilities and a team of dedicated experts, CRCP has become a trusted name in the industry for delivering superior products. These panels have quickly gained recognition for their ability to provide reliable and efficient solutions in various controlled environments.Paragraph 1: The Importance of Cleanroom EnvironmentsCleanrooms are crucial in multiple industries, including pharmaceuticals, biotechnology, electronics, healthcare, and aerospace. These controlled environments maintain a highly controlled level of cleanliness, preventing particles such as dust, microbes, and chemical vapors from contaminating sensitive processes. As the demand for cleaner production environments has increased over the years, CRCP has emerged as a market leader in maintaining the highest standards of quality and innovation in cleanroom composite panels.Paragraph 2: CRCP's Commitment to Quality and InnovationCRCP is committed to providing its customers with the most advanced cleanroom panels available in the market today. Their panels are engineered using innovative composite technology that combines materials with exceptional thermal, mechanical, and chemical resistance properties. This ensures the longevity and performance of CRCP panels in even the most demanding cleanroom environments.Paragraph 3: State-of-the-Art Production FacilitiesThe company possesses modern production facilities that adhere to stringent quality control measures and follow industry best practices. The manufacturing process integrates cutting-edge equipment and automated systems to guarantee the consistency and precision of each panel. CRCP also employs a highly skilled workforce that contributes to the company's capabilities to deliver products of the highest quality to clients worldwide.Paragraph 4: Versatility and Customization OptionsCRCP understands the diverse needs of industries requiring cleanroom environments. To meet these specific requirements, CRCP offers a wide range of panel options in terms of thickness, sizes, and finishes. The company's technical experts work closely with clients to understand their unique needs and develop tailored solutions. Additionally, CRCP constantly invests in research and development to ensure their panels' compatibility with the latest technological advancements.Paragraph 5: Industry ApplicationsClean Room Composite Panels find extensive application in a variety of industries. In the pharmaceutical sector, CRCP panels are commonly used for the manufacturing of drugs and sterile medical devices to prevent cross-contamination. The aerospace industry relies on CRCP panels to maintain the cleanliness and air quality necessary during the assembly of highly sensitive equipment. Electronics manufacturing also benefits from these panels since they provide protection against electrostatic discharge (ESD) and ensure the integrity of sensitive electronic components.Paragraph 6: Sustainability InitiativesCRCP is committed to promoting sustainability in its manufacturing processes. They prioritize the use of eco-friendly materials, optimize energy consumption during production, and implement efficient waste management practices. CRCP's dedication to sustainability ensures the reduction of their environmental footprint while producing panels that adhere to the highest standards of cleanliness and performance.Conclusion:Clean Room Composite Panels (CRCP) is revolutionizing the way controlled environments are created and maintained. The company's commitment to excellence, innovation, versatility, and sustainability makes them a reliable and trusted partner for industries requiring cleanroom solutions. With their advanced composite technology and constant drive for improvement, CRCP is poised to continue playing a key role in shaping the cleanroom industry for years to come.

Exploring the Advantages of Modular Cleanroom Panels for Enhanced Cleanroom Efficiency

Modular Cleanroom Panel Revolutionizes Sterile EnvironmentsIn the rapidly evolving field of technology and innovation, advancements are constantly being made to enhance safety and efficiency. One such pivotal development has been the introduction of Modular Cleanroom Panels, a groundbreaking solution that has revolutionized sterile environments across various industries.Cleanrooms are specialized environments used in industries such as pharmaceuticals, biotechnology, electronics, and healthcare, where the utmost cleanliness and sterility are required. These controlled environments are vital for research, manufacturing, and other critical processes. To meet the stringent requirements of these industries, traditional cleanrooms have relied on fixed structures that are often expensive, time-consuming to install, and inflexible to adapt to changing needs.However, with the advent of Modular Cleanroom Panels, these challenges have been overcome effectively. These panels, manufactured by {company name}, provide a flexible, customizable, and cost-effective solution. Designed to be easily assembled and disassembled, these panels offer a modular approach to cleanroom construction that ensures adaptability and scalability.Featuring a combination of durable materials and cutting-edge technology, the Modular Cleanroom Panels offer an airtight and sterile enclosure. These panels are manufactured in accordance with industry standards and guidelines to guarantee the highest level of cleanliness and safety. Each panel undergoes rigorous quality testing, ensuring that it meets or exceeds the regulatory requirements of sterile environments.What sets the Modular Cleanroom Panels apart is their unique design that allows for quick installation and reconfiguration. Traditional cleanrooms often require substantial time and effort for installation, causing delays and hindering productivity. However, with the Modular Cleanroom Panels, businesses can drastically reduce setup time and operational downtime. Whether it is expanding the existing cleanroom or relocating it altogether, these panels offer an unprecedented level of flexibility without compromising on integrity or performance.The versatility of the Modular Cleanroom Panels extends to their ability to integrate seamlessly with existing infrastructure. They can be easily connected to HVAC systems, lighting, and other facilities, allowing for an all-encompassing cleanroom experience. These panels can also accommodate various door types, windows, pass-throughs, and other essential features, ensuring that diverse functional requirements are met.Moreover, the innovative design of the Modular Cleanroom Panels addresses the need for environmental sustainability. With their modular nature, these panels can be reused, repurposed, and adapted to changing needs, reducing waste generation. Additionally, their energy-efficient construction promotes long-term cost savings while minimizing the carbon footprint.From pharmaceutical production to semiconductor manufacturing, the applications of Modular Cleanroom Panels are vast and diverse. Their adoption has proven to be a game-changer for businesses around the globe. By providing a solution that is both cost-effective and efficient, the panels contribute to improved operational efficiency, enhanced product quality, and a reduced risk of contamination.{Company name}, the leading manufacturer of Modular Cleanroom Panels, has been at the forefront of this technological breakthrough. With years of experience and expertise, the company has a deep understanding of the demands and challenges faced by industries operating in sterile environments. Their commitment to delivering high-quality cleanroom solutions has made them a trusted partner for businesses globally.As the demand for cleanrooms continues to grow, the Modular Cleanroom Panels offer a path-breaking solution to the inherent limitations of traditional cleanrooms. By combining flexibility, adaptability, and efficiency, these panels are set to shape the future of sterile environments. With their ability to create customized and easily configurable cleanrooms, modules will undoubtedly play a vital role in catering to the evolving needs of industries that prioritize cleanliness and sterility.

New Air Purifier Model 10 Offers Advanced Environment-Friendly Features - Check Out the Latest Developments

Title: Cutting-Edge Air Purification System Unveiled: Envirco's Revolutionary Mac 10Introduction:Envirco, a leading innovator in air filtration systems, has unveiled its groundbreaking air purification system, the Mac 10. The Mac 10 is poised to revolutionize indoor air quality by effectively eliminating harmful particles, contaminants, and pollutants. Designed with advanced technologies and built by a team of experts, this state-of-the-art system sets a new standard in air purification.With an increasing global focus on improving indoor air quality for health and safety reasons, the Mac 10 comes as a timely solution. Its innovative features and exceptional performance make it an essential tool across various sectors including healthcare, commercial spaces, educational institutions, and hospitality.Unmatched Performance and Efficiency:At the forefront of the Mac 10's exceptional performance is its proprietary air filtration system. Equipped with a high-efficiency particulate air (HEPA) filter, the Mac 10 effectively removes up to 99.97% of airborne particles as small as 0.3 micrometers. This includes dust, pollen, dander, mold spores, and even bacteria and viruses.Additionally, the Mac 10 boasts adjustable fan speed settings, allowing users to customize the airflow according to their specific needs. The system can efficiently cycle the air in a room multiple times per hour, ensuring a constant supply of purified air.Seamless Design and Versatility:Envirco's commitment to providing a user-friendly experience is evident in the Mac 10's seamless design. The system is engineered to be easily installed in various settings, offering flexibility in both portable and fixed applications. Its compact size and lightweight nature enable hassle-free mounting on walls, ceilings, or even as standalone units.Furthermore, the Mac 10 is equipped with an intuitive control panel, enabling precise adjustments and monitoring of air quality parameters. The system also incorporates sensors that continuously analyze the air and provide real-time data on the levels of pollutants and contaminants. Users can easily access this information through a digital display and make informed decisions to maintain optimal indoor air quality.Sustainable and Eco-Friendly:As environmental concerns continue to shape consumer choices, the Mac 10's sustainability features make it an attractive option. The system is designed and built with environmentally friendly materials, ensuring minimal ecological impact throughout its lifecycle.Envirco's focus on energy efficiency is evident in the Mac 10's low power consumption. Intelligent energy-saving modes ensure that the system operates at optimal levels while minimizing energy wastage. This not only reduces operating costs but also contributes to a greener, more sustainable future.Comprehensive Support and Maintenance:Envirco's commitment to customer satisfaction extends beyond the purchase. The Mac 10 comes with a comprehensive support package, including professional installation, maintenance, and after-sales service. This ensures that customers receive the necessary guidance and assistance to maximize the system's performance and longevity.The system's modular design allows for easy filter replacement and routine maintenance, further simplifying upkeep. With regular servicing, the Mac 10 guarantees consistent and efficient air filtration for years to come.Conclusion:Envirco's innovative Mac 10 air purification system sets a new benchmark in indoor air quality standards. With its exceptional performance, seamless design, sustainability features, and comprehensive support, the Mac 10 is poised to become a game-changer in various industries.As the world continues to prioritize the health and well-being of occupants in indoor environments, Envirco's Mac 10 offers a reliable and efficient solution. By effectively removing harmful particles, contaminants, and pollutants, the Mac 10 creates an environment conducive to productivity, comfort, and overall well-being.

Discover the Benefits of using a High-Quality Cleanroom Workstation

Title: Cutting-Edge Cleanroom Workstation Boosts Efficiency in Manufacturing FacilitiesIntroduction:In the fast-paced world of manufacturing, maintaining high levels of cleanliness and sterility is of utmost importance. This is where the innovative Cleanroom Workstation, developed by an industry-leading company, comes into play. The Cleanroom Workstation offers unparalleled performance, ensuring the highest standards for cleanliness, while also improving efficiency and productivity in manufacturing facilities worldwide.[Company Name], a renowned manufacturer specializing in advanced cleanroom technology, has unveiled their state-of-the-art Cleanroom Workstation. Designed to meet the increasing demands of the industry, this cutting-edge workstation combines innovative features with precision engineering to deliver exceptional results. Let us delve deeper into the functional aspects and benefits of this groundbreaking product.Unparalleled Cleanliness Standards:The Cleanroom Workstation is designed from the ground up to provide a controlled environment with stringent cleanliness standards. The workstation provides a highly filtered and controlled environment that effectively removes and traps airborne particles, microbes, and other pollutants, ensuring airtight quality control. By incorporating advanced HEPA and ULPA filtration systems, the workstation ensures that the air quality inside the facility surpasses industry standards, eliminating the risk of contamination and guaranteeing optimal production conditions.Versatile Configurations:Understanding the diverse requirements of different manufacturing processes, the Cleanroom Workstation offers customizable configurations to suit specific needs. With the ability to accommodate various levels of cleanliness and complexity, the workstation can be tailored to cater to a wide range of industries, including pharmaceuticals, electronics, medical devices, cosmetics, and food processing. This flexibility allows manufacturing facilities to maximize their efficiency and meet strict regulatory guidelines without compromising on cleanliness or functionality.Enhanced Ergonomics and Efficiency:The Cleanroom Workstation is built with ergonomics in mind, with a focus on creating a user-friendly working environment. The workstation provides a comfortable and efficient workspace for operators, ensuring optimal working conditions even during long production hours. Equipped with innovative features such as adjustable lighting, temperature, and humidity controls, the workstation optimizes the productivity and well-being of employees. This boosts the efficiency of manufacturing processes, resulting in increased output and improved overall quality of the final products.Seamless Integration of Advanced Technologies:With technological advancements continuously reshaping the manufacturing landscape, the Cleanroom Workstation seamlessly integrates cutting-edge technologies. This includes automated monitoring systems that constantly track environmental conditions, ensuring optimal levels of cleanliness at all times. Additionally, the workstation allows for easy integration of robotic systems, aiding in streamlining operations and increasing precision and speed. The ability to integrate smart manufacturing technologies adds a layer of sophistication to the workstation, making it a future-proof solution for manufacturing facilities of all sizes.Sustainable and Cost-Effective Solution:As sustainability becomes a central focus in manufacturing operations, the Cleanroom Workstation aligns with the industry's growing emphasis on environmentally friendly practices. The workstation utilizes energy-efficient components and processes, reducing energy consumption and minimizing its ecological footprint. Furthermore, the workstation is designed to support cost-effective manufacturing, optimizing resource utilization and reducing waste generation. By minimizing downtime and maximizing productivity, the Cleanroom Workstation generates long-term cost savings, making it a smart investment for manufacturing facilities aiming for both sustainability and profitability.Conclusion:The introduction of the Cleanroom Workstation by [Company Name] marks a significant milestone in the manufacturing industry's ongoing pursuit of cleanliness, efficiency, and advanced technology integration. With its exceptional cleanliness standards, versatile configurations, enhanced ergonomics, and seamless integration of advanced technologies, the workstation stands at the forefront of modern manufacturing practices.By embracing this state-of-the-art technology, manufacturers can achieve unmatched levels of cleanliness, improve productivity, and meet stringent regulatory requirements, ensuring the delivery of high-quality products to global markets. The Cleanroom Workstation represents not only a technological advancement but also a commitment to excellence and innovation in the manufacturing sector.