Discover the Practicality of a Portable Cleanroom Hood for Optimal Cleanliness

By:Admin

[Company Introduction]

In today's fast-paced and rapidly evolving world, industries such as pharmaceuticals, biotechnology, and electronics are constantly seeking innovative solutions to ensure clean and controlled environments. Recognizing the significance of this need, our company has developed an exemplary product, the Portable Cleanroom Hood. This cutting-edge technology provides businesses with a portable and efficient solution to maintain cleanliness and sterility, thus meeting stringent industry standards and regulations.

With our commitment to delivering unparalleled products, we strive to revolutionize the way industries maintain a clean environment. Our Portable Cleanroom Hood not only helps maintain sterile conditions but also enhances workflow efficiency, reduces particle contamination, and ensures the safety of both products and personnel. Over the years, our company has garnered a reputation for excellence, standing as a trusted partner for businesses across various industries.

[Product Description]

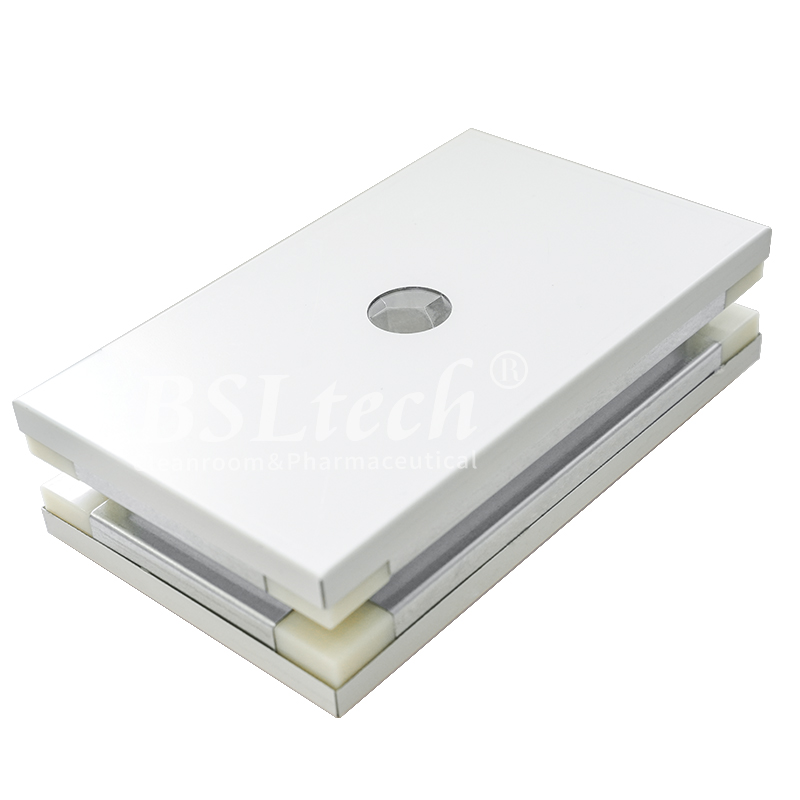

The Portable Cleanroom Hood is an exceptional product designed to create an isolated and controlled environment, enabling businesses to perform critical operations with precision and confidence. This lightweight and easy-to-use hood features a durable polypropylene construction, ensuring long-lasting performance and easy maintenance.

Equipped with high-efficiency particulate air (HEPA) filters, the Portable Cleanroom Hood effectively removes up to 99.99% of dust particles, ensuring the purity and sterility of the environment. The filtration system operates at low noise levels, enhancing comfort and focus for personnel working in the vicinity.

Additionally, the hood integrates adjustable airflow controls, allowing users to customize ventilation settings according to specific requirements. This flexibility ensures an optimal environment for delicate procedures and operations that demand ultra-clean conditions. The control panel, conveniently positioned on the hood, enables easy adjustment of these settings, ensuring a user-friendly experience.

One of the key features of the Portable Cleanroom Hood is its mobility. With its compact design and sturdy wheels, the hood can be easily maneuvered to different areas within a facility. This versatility allows businesses to meet evolving operational needs and maintain clean environments across various workstations.

[Industry Applications]

The applications of the Portable Cleanroom Hood span across multiple industries, where maintaining a sterile and controlled environment is crucial. In the pharmaceutical industry, for example, the hood is indispensable for operations such as compounding sterile preparations, drug research and development, and aseptic filling. Its portability allows pharmaceutical companies to carry out these essential tasks in different areas, ensuring adherence to stringent industry guidelines.

Similarly, the Portable Cleanroom Hood plays a vital role in biotechnology laboratories where researchers handle sensitive samples and conduct experiments requiring contamination-free environments. It allows scientists to maintain sterile conditions while handling DNA samples, cell cultures, and other fragile materials.

Furthermore, industries such as electronics and semiconductor manufacturing heavily rely on cleanroom environments to ensure the optimal functioning of their delicate products. The Portable Cleanroom Hood provides these industries with an added advantage of portability, enabling them to perform critical operations in different production areas without compromising on sterile conditions.

[Conclusion]

In conclusion, the Portable Cleanroom Hood stands as a game-changer for industries that depend on maintaining clean, sterile, and controlled environments. With its innovative design, advanced filtration system, and remarkable portability, this product has the potential to revolutionize the way businesses operate. By incorporating the Portable Cleanroom Hood into their workflows, industries can enhance productivity, improve product quality, and ensure the safety of both personnel and consumers.

Our company's commitment to excellence and continuous innovation positions us as a leading provider of cleanroom solutions. With the Portable Cleanroom Hood, we strive to empower businesses across various industries, assisting them in meeting industry standards and overcoming operational challenges. As we move forward, we remain dedicated to developing cutting-edge technologies that advance industries towards a cleaner and safer future.

Company News & Blog

Discover the Latest Innovation in Cleanroom Panels as Unveiled in Recent News

Title: High-Quality Cleanroom Panels Revolutionize Industry StandardsSubtitle: Top Manufacturing Company Introduces Innovative Cleanroom Panels for Enhanced PerformanceIntroduction:In a transformative step towards redefining industry standards, a leading manufacturing company has unveiled its cutting-edge cleanroom panels. These state-of-the-art panels, developed by one of the industry pioneers, AES Cleanroom Panels, promise to revolutionize the cleanroom sector with their unrivaled quality and advanced features.Industry leaders have long recognized the paramount importance of maintaining contaminant-free environments in sensitive sectors such as pharmaceuticals, electronics, and healthcare. The ability to control airborne particles, temperature, humidity, and pressure is crucial for the successful operation of facilities in these industries. AES Cleanroom Panels, with their innovative design and meticulous construction, ensure the highest standards of cleanliness and functionality.Unleashing Unparalleled Cleanroom Performance:AES Cleanroom Panels are specifically engineered to provide optimal performance and meet the strictest cleanroom requirements. Achieving ISO 14644-1 Class 5 and GMP (Good Manufacturing Practice) standards, these panels ensure the highest level of air filtration, reducing airborne contaminants and promoting a sterile workspace.The secret behind the exceptional performance lies in the advanced materials utilized during construction. AES Cleanroom Panels are constructed from non-porous, non-shedding materials, such as coated steel, glass, or aluminum. This not only prevents the retention of particles but also facilitates easy cleaning and maintenance, ensuring long-lasting use.Moreover, the company uses cutting-edge technology in manufacturing these panels. Their innovative modular design allows for quick and hassle-free installation, providing significant time and cost savings. Each individual component is precision-engineered to fit securely together, ensuring an airtight seal and reducing the possibility of leaks or air bypass.Expanded Applications and Customization:Recognizing the diverse needs of cleanroom operators, AES Cleanroom Panels cater to various industry requirements. From pharmaceutical manufacturing and medical research to microelectronics and food processing, these panels have proven adaptable and versatile across a wide range of applications.Furthermore, the company offers customization options to meet specific client demands. Whether it is a unique size requirement, specific finishes, or integration of specialized equipment, AES Cleanroom Panels can tailor their products accordingly. This flexibility enables cleanroom operators to optimize their workspace for efficiency and productivity, ensuring a seamless workflow.Commitment to Sustainability:AES Cleanroom Panels stand out not only for their performance but also for their environmentally conscious approach. The company incorporates sustainable practices in their manufacturing processes, ensuring minimal waste production and reduced carbon footprints. By using recyclable materials and minimizing the use of volatile organic compounds (VOCs), their cleanroom panels contribute to a greener future.Collaborative Partnerships and Stellar Customer Support:With a well-established reputation for excellence, AES Cleanroom Panels have forged collaborative partnerships with industry leaders worldwide. These partnerships enable the company to stay at the forefront of cleanroom technology, delivering innovative products that surpass expectations.Furthermore, AES Cleanroom Panels is committed to providing unparalleled customer support. Their team of experts offers personalized assistance in everything from project consultation and planning to installation and after-sales service. This unwavering commitment to customer satisfaction has earned them a loyal clientele, who trust and rely on their products for their cleanroom needs.Conclusion:AES Cleanroom Panels have emerged as a game-changer in the cleanroom industry. By combining cutting-edge technology, unparalleled performance, customization options, and an environmentally conscious approach, the company has set new benchmarks for cleanroom panels. As industries strive to maintain clean and controlled environments, AES Cleanroom Panels provide the perfect solution, helping businesses meet the demands of an ever-evolving world.

Enhancing Safety and Hygiene: A Guide to Clean Room Doors

Clean Room Door: Delivering Excellence in Contamination ControlIn the quest for maintaining high standards of cleanliness and hygiene, clean room technology has become indispensable across various industries. From pharmaceuticals to electronics, clean rooms play a crucial role in ensuring product quality and reliability. At the forefront of this technological advancement is Clean Room Door, a leading provider of contamination control solutions.Clean Room Door, a brand renowned for its expertise in clean room systems, offers a wide range of specialized clean room doors that are tailored for various industries. With a focus on innovation and customer satisfaction, the company has carved a niche for itself in the highly competitive market.At the heart of Clean Room Door's success lies their commitment to manufacturing excellence. The company utilizes cutting-edge technology and state-of-the-art facilities to create doors that meet the stringent requirements of clean room environments. With a team of experienced engineers and designers, Clean Room Door ensures that each product is precision-engineered to provide optimal performance.One of Clean Room Door's flagship products is their hermetically sealed door, designed specifically for pharmaceutical clean rooms. These doors are built to eliminate any risk of air contamination, ensuring a sterile environment for the production of life-saving medications. With features such as seamless construction, airtight seals, and easy-maintenance, Clean Room Door's hermetically sealed doors have gained widespread acclaim in the pharmaceutical industry.Another key product offered by Clean Room Door is their fire-rated clean room door. Built to withstand extreme temperatures and prevent the spread of fire, these doors provide an added layer of safety and protection in clean room facilities. With compliance to international safety standards, Clean Room Door's fire-rated doors have become a preferred choice for industries where fire safety is of paramount importance.Clean Room Door's dedication to customer satisfaction extends beyond product quality. The company also provides comprehensive installation and maintenance services to ensure optimal performance of their clean room doors. Their team of skilled technicians works closely with clients to ensure seamless installation, offering post-installation support and regular maintenance checks to maximize the lifespan of their products.Recognizing the importance of customization, Clean Room Door also offers a wide range of options to tailor their clean room doors to specific requirements. From different sizes and finishes to specialized features such as electronic interlocks and access controls, Clean Room Door strives to provide flexible solutions that meet the unique needs of each customer.In addition to their commitment to excellence, Clean Room Door is also deeply committed to environmental sustainability. The company adheres to stringent environmental regulations and employs eco-friendly manufacturing practices to minimize their carbon footprint. By utilizing energy-efficient materials and optimizing production processes, Clean Room Door ensures that their products contribute to a greener and more sustainable future.Clean Room Door's impressive track record is a testament to their dedication and passion for clean room technology. With a focus on delivering excellence in contamination control, the company continues to innovate and expand its product offerings to meet the evolving needs of the industry. By combining cutting-edge technology, precision engineering, and a customer-centric approach, Clean Room Door is poised to maintain its position as a leader in the clean room solutions market for years to come.

Discover the Benefits of a Laminar Air Flow Chamber for Optimal Air Quality

Introducing the Next Generation Laminar Air Flow Chamber Revolutionizing Cleanroom Technology[Company Name], a renowned leader in technological advancements, is proud to introduce its latest innovation in cleanroom technology - the next generation Laminar Air Flow Chamber. With a commitment to ensuring the highest standards of cleanliness and safety, this cutting-edge product is set to revolutionize cleanroom environments across various industries.The Laminar Air Flow Chamber, designed and developed by our team of experts, is a state-of-the-art solution aimed at providing an ultra-clean airflow in controlled environments, allowing for the protection of sensitive materials, processes, and personnel. It offers a wide range of applications in the pharmaceutical, electronics, healthcare, research, and manufacturing sectors, among others.At the core of this innovative technology is a highly efficient filtration system, capable of removing submicron-sized particles from the airflow, ensuring a stringent level of cleanliness within the chamber. This enables our customers to create and maintain a contamination-free environment, vital for the success of critical operations and processes.The Laminar Air Flow Chamber boasts multiple advanced features that set it apart from traditional cleanroom solutions. Its cutting-edge design optimizes laminar airflow, creating a unidirectional, particle-free environment inside the chamber. This ensures a constant flow of ultra-clean air, effectively minimizing the risk of contamination and enhancing the quality of production, research, and experimentation.One of the standout features of our Laminar Air Flow Chamber is its versatility. The modular design allows for easy customization, ensuring compatibility with a wide array of equipment and processes. Whether it's pharmaceutical compounding, electronics assembly, or laboratory research, our solution can be tailored to meet specific requirements, making it highly adaptable to diverse industry needs.Additionally, the Laminar Air Flow Chamber prioritizes energy efficiency. Equipped with state-of-the-art sensors and controls, it dynamically adjusts the air volume based on real-time requirements, optimizing energy usage and reducing overall operational costs. With sustainability at the forefront of our minds, this product helps contribute to a greener and more environmentally friendly future.Furthermore, the Laminar Air Flow Chamber places high emphasis on user-friendly features and ergonomics. Its intuitive control panel allows for easy operation and monitoring, ensuring simplicity in adjusting settings as per user requirements. The chamber's ergonomic design focuses on the comfort and safety of personnel, reducing fatigue and optimizing productivity.At [Company Name], we understand the critical importance of maintaining a clean and controlled environment. Our commitment to technological excellence and continuous innovation helps us pioneer solutions that meet and exceed industry standards. The Laminar Air Flow Chamber is a testament to our dedication to providing cutting-edge cleanroom technology that can enhance operational efficiency, product quality, and ultimately, customer satisfaction.As we embrace this new era of cleanroom technology, we invite industry professionals, researchers, and stakeholders to experience the breakthrough capabilities of our Laminar Air Flow Chamber. With an unmatched ability to safeguard critical processes and personnel, our innovation promises to redefine the concept of cleanroom environments and drive advancements in a multitude of industries.In conclusion, [Company Name]'s latest introduction of the Laminar Air Flow Chamber establishes a new benchmark in cleanroom technology. Combining the highest standards of cleanliness, versatility, energy efficiency, and user-friendliness, our product is poised to enhance productivity, safety, and quality across various sectors. Embrace the future with our revolutionary solution and experience unparalleled performance in your cleanroom operations.

Top Benefits of Hepa Fan Filter Units for Improved Air Quality in Your Space

Title: Innovative Hepa Fan Filter Unit Revolutionizes Indoor Air QualityIntroduction: In a bid to address the increasing concerns about indoor air pollution, a leading company has unveiled their latest innovation - the Hepa Fan Filter Unit. With air quality rapidly deteriorating due to various factors such as urbanization, pollutants, and allergens, this state-of-the-art product promises to provide a refreshing solution to combat poor indoor air quality. Through the utilization of advanced technology and superior design, the Hepa Fan Filter Unit aims to become a game-changer in the industry, revolutionizing how we breathe and live in enclosed spaces.[Company Name], a renowned manufacturer in the field of air purification systems, has been at the forefront of developing groundbreaking technologies that enhance air quality. The introduction of the Hepa Fan Filter Unit marks yet another milestone achievement for the company, reinforcing their commitment to improving the health and well-being of individuals through innovative solutions.I. Problem Statement: Indoor Air Pollution and its EffectsIndoor air pollution has become a pressing concern, with a plethora of studies linking it to various health issues, including respiratory diseases, allergies, and even cardiovascular problems. Pollutants such as dust, pollen, pet dander, and volatile organic compounds (VOCs) are commonly found in indoor environments, leading to discomfort and adverse health effects.To combat this rising issue, conventional air purifiers have been used extensively. However, these systems often fall short in terms of efficiency, aesthetics, and noise levels, posing limitations to their overall effectiveness. Therefore, the introduction of the Hepa Fan Filter Unit serves as a vital advancement in the realm of indoor air purification.II. The Innovative Solution: Hepa Fan Filter UnitThe Hepa Fan Filter Unit is designed with cutting-edge technology that combines high-performance HEPA (High-Efficiency Particulate Air) filtration with a powerful yet silent fan. This unique combination ensures the effective removal of over 99.97% of airborne particles as small as 0.3 microns, providing an unprecedented level of indoor air quality.The unit operates by pulling in ambient air from the surrounding environment, which then passes through a multi-layered filtration system. The HEPA filter, consisting of numerous interlacing fibers, traps contaminants, including dust, pollen, bacteria, and even certain viruses. This advanced HEPA filtration technology acts as a barrier against harmful particles, while simultaneously improving the overall clarity and freshness of the air.III. Features and Benefits of the Hepa Fan Filter Unit1. Powerful Fan: The Hepa Fan Filter Unit is equipped with a powerful fan that efficiently circulates the filtered air throughout the space, ensuring homogeneous air quality distribution.2. Whisper-quiet Operation: The unit's advanced design minimizes noise emissions to nearly silent levels, creating a peaceful and undisturbed environment for users.3. Versatile Design: The sleek and modern design of the Hepa Fan Filter Unit seamlessly blends with any indoor setting, offering an aesthetically pleasing addition to homes, offices, hospitals, and other enclosed spaces.4. User-friendly Controls: The device comes with an intuitive control panel, allowing users to easily adjust fan speed, enable sleep mode, and monitor filter status for maintenance.IV. Conclusion: A Cleaner, Healthier FutureIndoor air pollution has become an alarming issue, affecting millions of individuals worldwide. The introduction of the Hepa Fan Filter Unit represents a significant step forward in combating this problem by providing an efficient, innovative, and aesthetically pleasing solution. With its exceptional air filtration capabilities, whisper-quiet operation, and user-friendly design, this novel product has the potential to improve the lives and well-being of occupants in various indoor environments. As [Company Name] continues its commitment to developing cutting-edge technologies, the Hepa Fan Filter Unit sets a new standard in indoor air quality and represents a cleaner, healthier future for all.

Top-Quality Clean Room Partition Panels: Enhancing Safety and Efficiency

Clean Room Partition Panels: Providing Advanced Solutions for Cleanroom EnvironmentsIn today's ever-evolving world, technologies are rapidly advancing, and industries are constantly striving to improve the quality of their products. Cleanrooms have emerged as crucial environments in various industries, such as pharmaceuticals, electronics, and healthcare, where contamination control is of utmost importance. Clean Room Partition Panels, developed by a leading industry player, are revolutionizing the concept of cleanroom construction by providing advanced partitioning solutions.Cleanroom environments require meticulous attention to detail and the strict adherence to specific standards and guidelines. The primary aim is to minimize the presence of particles, microorganisms, and other contaminants that could compromise the quality of production processes. Clean Room Partition Panels offer a comprehensive solution that allows for the efficient and effective control of particles, airflows, temperature, humidity, and pressure within these critical environments.The company behind Clean Room Partition Panels, known for its expertise and engineering excellence, has solidified its position as a trusted provider of cleanroom solutions. With years of experience and a vast portfolio of successfully completed projects, they have garnered a reputation for delivering cutting-edge products tailored to meet the unique requirements of various industries.One of the key aspects that sets Clean Room Partition Panels apart is their modular design. These panels are manufactured using high-quality materials, including stainless steel, aluminum, and non-shedding polymers. The modular design allows for easy installation and reconfiguration, offering flexibility and adaptability to changing cleanroom designs and requirements. Their lightweight construction minimizes structural load and facilitates quick and hassle-free installation processes.Clean Room Partition Panels are also equipped with advanced filtration systems, which play a crucial role in maintaining the desired air cleanliness levels. These panels integrate HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Particulate Air) filters to capture particles as small as 0.3 microns and 0.12 microns, respectively. By effectively filtering the air, these partition panels significantly reduce the risk of contamination, ensuring the integrity of processes taking place within the cleanroom.Furthermore, the company recognizes the importance of ergonomic design in cleanroom environments. Clean Room Partition Panels are engineered to provide not only a controlled environment but also a comfortable workspace for cleanroom personnel. The panels are designed to minimize air turbulence and reduce noise levels, enhancing the overall working conditions within the cleanroom.The versatility of Clean Room Partition Panels allows for seamless integration with other essential cleanroom components, such as air handling systems, lighting fixtures, and pass-through chambers. These panels are meticulously engineered to create airtight seals and eliminate potential leakages, ensuring the integrity of the controlled environment.The company's commitment to sustainability is also evident in the manufacturing process of Clean Room Partition Panels. They strive to minimize their environmental footprint by utilizing energy-efficient materials and reducing waste generation. The panels are designed for long-term durability and are easily recyclable, further contributing to the company's sustainability goals.Clean Room Partition Panels have already been successfully implemented in various cleanroom projects across different industries. Their exceptional performance and ability to meet stringent cleanroom standards have earned them recognition as a reliable and innovative solution for contamination control.In conclusion, Clean Room Partition Panels, developed by an industry-leading company, are transforming cleanroom construction with their advanced modular design, exceptional filtration systems, and ergonomic features. By providing solutions that safeguard the integrity of cleanroom environments, these panels are playing a crucial role in enhancing the quality and reliability of products across diverse industries. With an unwavering commitment to sustainability and continuous innovation, Clean Room Partition Panels are set to shape the future of cleanroom technologies.

Highly Efficient and Cost-effective Prefab Clean Rooms—A Game-Changer in Cleanroom Technology

Portable Modular Clean Rooms Revolutionize Cleanroom IndustryInnovative Prefab Clean Rooms have emerged as the latest trend in the cleanroom industry. These cutting-edge cleanrooms are completely customizable, cost-effective, and offer unmatched flexibility in terms of installation and usage. This disruptive technology has been developed by a pioneering company that has redefined the standards of cleanroom manufacturing.With the global need for controlled environments in various industries such as pharmaceuticals, biotechnology, medical devices, electronics, and aerospace, the demand for cleanrooms has witnessed exponential growth. Traditionally, constructing a cleanroom involved complex and time-consuming processes, such as custom designing, engineering, construction, and compliance with stringent industry regulations.Elevating the efficiency and convenience aspects, Prefab Clean Rooms have streamlined the cleanroom construction process. These modular cleanrooms are pre-fabricated offsite, ensuring consistent quality control and minimizing on-site disruptions. The company behind this game-changing technology leverages state-of-the-art manufacturing techniques and advanced materials to deliver cleanrooms that meet exact customer requirements.One of the key advantages of prefab cleanrooms is their portability. These cleanrooms can be easily relocated or expanded as per the changing needs of the industry. With traditional cleanrooms, relocation or reconfiguration involved significant downtime and financial investment. In contrast, Prefab Clean Rooms offer the flexibility to adapt to unforeseen circumstances or growing production requirements effortlessly.Moreover, Prefab Clean Rooms are highly cost-effective. Traditional cleanroom constructions required substantial capital investment due to the extensive labor, time, and materials involved. In contrast, prefab cleanrooms significantly reduce construction costs by minimizing the need for on-site labor and eliminating additional expenses associated with custom designs. The company's standardized modules keep costs under control, ensuring a quick return on investment without compromising on quality.The cleanroom manufacturing company has also focused on sustainability in its product design. Prefab Clean Rooms are built using eco-friendly materials and energy-efficient systems. The company prioritizes reducing waste generation, rational use of resources, and incorporating sustainable practices throughout the manufacturing process. This commitment to sustainability aligns with the increasing global emphasis on environmentally conscious business practices.The remarkable success of prefab cleanrooms can be attributed to their compliance with stringent industry standards. The manufacturing company ensures that its cleanrooms adhere to international regulations, including ISO, FDA, and cGMP guidelines. This guarantees that the cleanrooms provide a controlled environment, maintaining sterile conditions necessary for sensitive manufacturing processes. The company's commitment to quality and safety has earned it a stellar reputation in the cleanroom industry.Moreover, Prefab Clean Rooms can be customized to meet specific industry requirements. Whether it is a pharmaceutical company requiring a cleanroom for sterile drug manufacturing or a semiconductor manufacturer needing a controlled environment for precise electronics assembly, the modular cleanrooms can be configured to suit diverse needs. Offering complete flexibility, the company caters to a broad range of industries, ensuring customer satisfaction and market viability.To enhance customer experience further, the cleanroom manufacturing company provides comprehensive support services. Their dedicated team of experts assists customers in assessing their cleanroom requirements, designing the ideal modular layout, and ensuring seamless installation. The post-installation support includes regular maintenance and certification to ensure compliance with industry regulations and standards.Overall, Prefab Clean Rooms have revolutionized the cleanroom industry by providing a game-changing solution that breaks barriers in construction, efficiency, and flexibility. With their portability, cost-effectiveness, sustainability, compliance, and customization capabilities, these modular cleanrooms have become the go-to choice for industries seeking controlled environments. As the demand for cleanrooms rises across the globe, the company's extraordinary product offerings are poised to flourish and shape the future of cleanroom manufacturing.

Discover the Latest HEPA Fan Filter Unit for Cleanrooms

Title: Advanced Cleanroom HEPA Fan Filter Unit Enhances Air Purification in Critical EnvironmentsIntroduction:In today's context of increasing concern for air quality, proper air filtration systems play a crucial role in maintaining cleanliness and minimizing contamination in sensitive environments like cleanrooms. With that perspective, {Company Name} has developed an innovative Cleanroom HEPA Fan Filter Unit (FFU) that represents a significant leap forward in air purification technology. This cutting-edge solution combines advanced features, engineering excellence, and a commitment to superior performance, making it an ideal choice for critical environments that demand the highest standards of cleanliness.Paragraph 1: Cleanroom environments are utilized across a wide range of industries, including pharmaceuticals, biotechnology, microelectronics, and healthcare. In these sectors, even the smallest particles or contaminants in the air can have far-reaching implications on the quality of products and processes. Therefore, the introduction of an advanced FFU by {Company Name} serves as a remarkable development that addresses the critical need for efficient filtration systems.Paragraph 2:The novel HEPA Fan Filter Unit offered by {Company Name} boasts cutting-edge HEPA filtration technology. The High-Efficiency Particulate Air (HEPA) filters are designed to remove 99.97% of particles as small as 0.3 microns, offering exceptional protection against microorganisms, dust, pollen, and other harmful particles. This superior level of filtration enhances air quality while significantly reducing the risk of contamination, surpassing industry standards.Paragraph 3:The combination of a powerful fan and advanced filtration technology enables the FFU to deliver a high volume of clean air, ensuring rapid and efficient air circulation within cleanroom spaces. The powerful fan system is meticulously engineered to provide optimal air velocity while maintaining low noise levels, creating a favorable environment for workers without compromising cleanliness.Paragraph 4:One of the distinguishing features of the {Company Name} FFU is its adaptability and flexibility in various cleanroom settings. With its compact design and easy installation, these units can be effortlessly integrated into both new cleanroom designs and existing facilities. Additionally, the FFU's modular construction allows for easy maintenance and filter replacements, reducing downtime and maximizing operational efficiency.Paragraph 5:Moreover, {Company Name} puts emphasis on the energy efficiency of their FFU, ensuring long-term cost savings for end-users. By employing advanced technology, the FFU optimizes air distribution and reduces energy consumption without compromising the overall performance. This commitment to sustainability showcases {Company Name}'s dedication to developing environmentally conscious solutions.Paragraph 6:To guarantee the reliability and quality of their FFU, {Company Name} subjects their products to rigorous quality control measures throughout the manufacturing process. Committed to meeting international standards, the company employs stringent testing protocols to ensure adherence to industry regulations, further instilling confidence in the product's reliability and durability.Paragraph 7:As strategic partners, {Company Name} has collaborated with numerous renowned cleanroom facilities to optimize their FFU's design and performance to meet the unique requirements of each industry. This close cooperation allows for continuous improvement and innovation, further solidifying {Company Name}'s position as a trusted partner in the cleanroom industry.Conclusion:In today's ever-demanding world, maintaining clean and contamination-free environments is paramount. With {Company Name}'s advanced Cleanroom HEPA Fan Filter Unit, organizations operating within critical environments can breathe easy knowing that their air filtration needs are in capable hands. The combination of cutting-edge HEPA filtration, powerful air circulation, adaptability, energy efficiency, and rigorous quality control protocols make this FFU a remarkable solution for cleanroom environments. As {Company Name} continues to evolve and innovate, their commitment to excellence and sustainability ensures a brighter and cleaner future for all industries relying on cleanrooms to achieve their goals.

Cleanroom Design and Construction: Creating a Sterile Environment for Optimal Results

Cleanroom Design And Construction is a leading provider of comprehensive cleanroom solutions for various industries. With their expertise in cleanroom design, construction, and certification, the company has established itself as a trusted name in the field.Cleanrooms play a critical role in industries such as pharmaceuticals, biotechnology, electronics, and aerospace, where maintaining a controlled environment is of utmost importance. These sterile environments are designed to minimize the presence of particulate matter, contaminants, and other pollutants that can potentially jeopardize the integrity of products or research.Cleanroom Design And Construction understands the essential requirements of different industries and provides tailored solutions to meet their unique needs. From initial design and layout to construction and validation, the company ensures that every aspect of the cleanroom is meticulously planned and executed.One of the key elements that sets Cleanroom Design And Construction apart from its competitors is their team of highly skilled professionals. The company employs experienced engineers, architects, and technicians who have a deep understanding of the intricacies involved in cleanroom design and construction. Their expertise enables them to deliver cutting-edge solutions while adhering to industry standards and regulations.Moreover, Cleanroom Design And Construction takes pride in its commitment to utilizing advanced technologies and innovative approaches. The company stays updated with the latest advancements in cleanroom design, filtration systems, and air monitoring equipment. By incorporating state-of-the-art technology into their projects, they ensure that clients receive the most efficient and reliable cleanroom solutions.Cleanroom Design And Construction's portfolio boasts a wide range of successful cleanroom projects across industries. They have provided cleanroom solutions for pharmaceutical manufacturing facilities, research laboratories, electronics assembly lines, and more. Each project is treated with utmost importance, regardless of its size or complexity. The company's attention to detail and dedication to client satisfaction have earned them a strong reputation in the market.In addition to designing and constructing cleanrooms, Cleanroom Design And Construction also offers ongoing maintenance services. Cleanrooms require regular monitoring, testing, and cleaning to sustain their desired performance levels. The company provides comprehensive maintenance packages to ensure that clients' cleanrooms continue to function optimally throughout their lifecycle.Cleanroom Design And Construction's commitment to quality is reflected in their certifications and affiliations. The company strictly adheres to international standards such as ISO 14644 and Good Manufacturing Practices (GMP). They are also associated with renowned industry organizations, further cementing their credibility and expertise.Overall, Cleanroom Design And Construction is a reliable partner for industries seeking exceptional cleanroom solutions. From initial design and construction to ongoing maintenance, the company's comprehensive services ensure that clients receive top-notch cleanrooms tailored to their specific requirements. With their commitment to quality, innovative approach, and experienced team, Cleanroom Design And Construction continues to lead the way in the cleanroom industry.

The Importance of Biosafety Cabinets in Promoting Safety and Containment

Title: Enhanced Safety Measures: Utilizing Advanced Biosafety Cabinets in LaboratoriesIntroduction: In an ever-evolving world of advanced scientific research and innovation, laboratory safety has never been more crucial. As research facilities strive to develop groundbreaking solutions to global challenges, such as pandemics, it is imperative that proper safety measures are in place to protect both researchers and the environment. One such measure gaining widespread recognition is the use of advanced biosafety cabinets. These cabinets, equipped with cutting-edge technology, ensure the highest level of protection and efficiency in laboratories. This article delves into the significance of biosafety cabinets in promoting safe laboratory practices, thereby promoting progress in scientific endeavors.I. Understanding Biosafety Cabinets:At its core, a biosafety cabinet (BSC) is an enclosed workspace which provides a sterile and controlled environment for scientists to handle potentially hazardous materials. BSCs are designed to protect both the user and the surrounding environment from biological agents, harmful chemicals, and other contaminants. They employ a combination of airflow systems, HEPA filtration, and effective containment strategies to achieve maximum safety and efficiency.BSCs are classified into three categories based on the level of protection they provide. Class I BSCs provide personnel and environmental protection, while Class II cabinets offer enhanced protection through HEPA-filtered air, protecting both the operator and sample from cross-contamination. The highest level of protection is achievable with Class III cabinets, which provide both maximum protection to the operator and the surrounding environment, as they are completely enclosed with gas-tight construction.II. Importance of Biosafety Cabinets:a) Operator Protection:BSCs offer a vital layer of protection to laboratory personnel, shielding them from potential exposure to harmful substances. The enclosed workspace ensures that hazardous materials are properly contained, preventing contamination through accidental spills or leaks. The airflow systems within the cabinets continuously filter air, trapping potential contaminants and reducing the risk of exposure to biohazards.b) Sample Protection:In addition to personnel safety, biosafety cabinets play a pivotal role in safeguarding sensitive research samples. HEPA filters featured in Class II BSCs create an ultra-clean air environment, effectively eliminating airborne particles and reducing the chances of cross-contamination. This significantly enhances the accuracy and reliability of experimental results, directly impacting the overall quality of scientific research outcomes.c) Environmental Protection:Laboratories heavily rely on biosafety cabinets to mitigate the risk of hazardous substances being released into the environment. By confining biohazardous materials and circulating the air through advanced filtration systems, BSCs prevent the spread of harmful agents both within the laboratory and beyond. This proactive approach ensures compliance with environmental regulations and minimizes the potential impact on public health.III. Industry-leading Biosafety Cabinet Solutions by [Company Name]:[Company Name] is a recognized name in the laboratory safety industry, dedicated to equipping research facilities with state-of-the-art biosafety cabinet solutions. With a rich history of technological innovation, [Company Name] offers cutting-edge BSC designs that prioritize user safety and operational efficiency.a) Advanced Engineering:[Company Name]'s biosafety cabinets incorporate advanced engineering principles to provide the highest level of protection to personnel, samples, and the environment. The cabinets exhibit low noise levels, optimal airflow, and ergonomic design, ensuring ease of use and improved productivity within laboratories.b) Versatility and Adaptability:Recognizing that different laboratories have unique requirements, [Company Name] offers a range of classes and sizes of biosafety cabinets. This versatility allows laboratories to select the most suitable cabinet based on their specific needs, catering to diverse research areas, such as microbiology, virology, and pharmaceutical development.c) Industry Compliance and Certification:[Company Name]'s biosafety cabinets comply with stringent industry regulations and standards to ensure the highest level of safety and reliability. Regular inspections and certifications guarantee that the cabinets meet or exceed the necessary guidelines, providing laboratories with confidence in their safety practices.Conclusion:As laboratories worldwide endeavor to overcome complex challenges, the role of biosafety cabinets in ensuring the safety of researchers and the integrity of research outcomes cannot be overstated. With the comprehensive protection they offer to personnel, samples, and the environment, biosafety cabinets have become an indispensable component of modern laboratory practices. By leveraging advanced engineering and certification standards, companies like [Company Name] continue to facilitate scientific breakthroughs and advancements, promoting a safer and more productive research landscape.

Discover the Versatility and Efficiency of Portable Laminar Flow Hoods

Portable Laminar Flow Hood Revolutionizes Cleanroom TechnologyCleanrooms have long been a crucial component of industries such as pharmaceuticals, electronics, and healthcare, where maintaining absolute cleanliness is paramount. These sterile environments protect products, equipment, and personnel from contamination, ensuring quality and safety. Traditionally, cleanrooms were large, fixed structures, limiting their accessibility and adaptability. However, a groundbreaking innovation is set to revolutionize cleanroom technology - the Portable Laminar Flow Hood.Developed by a leading technology company, whose mission is to provide cutting-edge solutions for cleanroom environments, the Portable Laminar Flow Hood is poised to transform the landscape of cleanroom operations. This compact yet powerful device integrates state-of-the-art laminar airflow technology, offering a versatile and efficient alternative to traditional cleanrooms.The key advantage of the Portable Laminar Flow Hood lies in its mobility. Unlike conventional cleanrooms, which often require significant investment and installation time, this innovative system can be easily transported and set up in various locations. With its lightweight design and compact dimensions, it eliminates the need for large-scale cleanroom infrastructure and enables users to create clean environments wherever necessary.The essential feature of the Portable Laminar Flow Hood is its laminar airflow system. Equipped with high-performance filters and a powerful fan, the device creates a controlled, ultra-clean airflow that ensures the removal of contaminants and particles from the working area. This laminar flow of sterile air creates a localized clean zone, protecting sensitive products, equipment, or processes from the risk of contamination.Furthermore, the Portable Laminar Flow Hood boasts advanced filtration technology, capable of capturing particles as small as 0.3 microns with an efficiency exceeding 99.9%. This level of filtration surpasses industry standards and guarantees a sterile working environment free from even the tiniest contaminants.The ease of use and adaptability of the Portable Laminar Flow Hood make it an ideal solution for various applications. In the pharmaceutical industry, for instance, it can be utilized during the manufacturing process to maintain sterile conditions and prevent cross-contamination. Similarly, in medical facilities, it can be employed for tasks that require a sterile environment, such as handling medications or performing delicate procedures.In addition to its mobility and top-notch performance, the Portable Laminar Flow Hood stands out for its energy efficiency. Unlike traditional cleanrooms, which consume a significant amount of energy to maintain airflow, this device is designed to be highly energy-efficient. Employing cutting-edge technologies such as variable speed control for the fan and LED lighting, it minimizes power consumption while providing optimal cleanroom conditions.Another noteworthy advantage of the Portable Laminar Flow Hood is its user-friendly interface and intuitive operation. Equipped with a digital control panel and user-friendly software, it allows for effortless adjustment of airflow speed, filter status monitoring, and alarm configuration. This streamlined operation reduces the learning curve, ensuring that even personnel with limited cleanroom experience can utilize the technology effectively.The Portable Laminar Flow Hood not only revolutionizes cleanroom technology but also contributes to environmental sustainability. Its energy-efficient design minimizes carbon emissions, lowers overall energy consumption, and reduces waste associated with traditional cleanroom systems. By adopting this innovative solution, industries can enhance their operational efficiency while minimizing their ecological footprint.In conclusion, the Portable Laminar Flow Hood represents a significant advancement in cleanroom technology. Its mobility, high-performance laminar airflow system, and energy efficiency make it a game-changer for industries that rely on cleanroom environments. With its potential to transform the way cleanrooms are utilized, this innovation ushers in a new era of efficiency, ease, and adaptability for industries worldwide.